GOST 33259 09G2S Mild Carbon Steel CT20 High Pressure Welding Neck Flange DN100 PN100

Lintlha tsa Sehlahisoa

| Lebitso la Sehlahiswa | GOST09G2SKhatello e Phahameng ea Welding Neck Flange | ||||||

| Boholo | 4″ DN100 | ||||||

| Khatello | PN100 | ||||||

| Sehlopha : | Tšepe ea sebopeho bakeng sa kaho ea welding | ||||||

| Botenya | 7850 lik'hilograma /m3 | ||||||

| Tšepe: | 09G2.09G2DT.09G2T.10G25 | ||||||

| Kopo | Likarolo tse fapaneng le likarolo tsa meaho ea tšepe e cheselitsoeng e sebetsang ka mocheso ho tloha -70 ho ea ho + 425 ° C. | ||||||

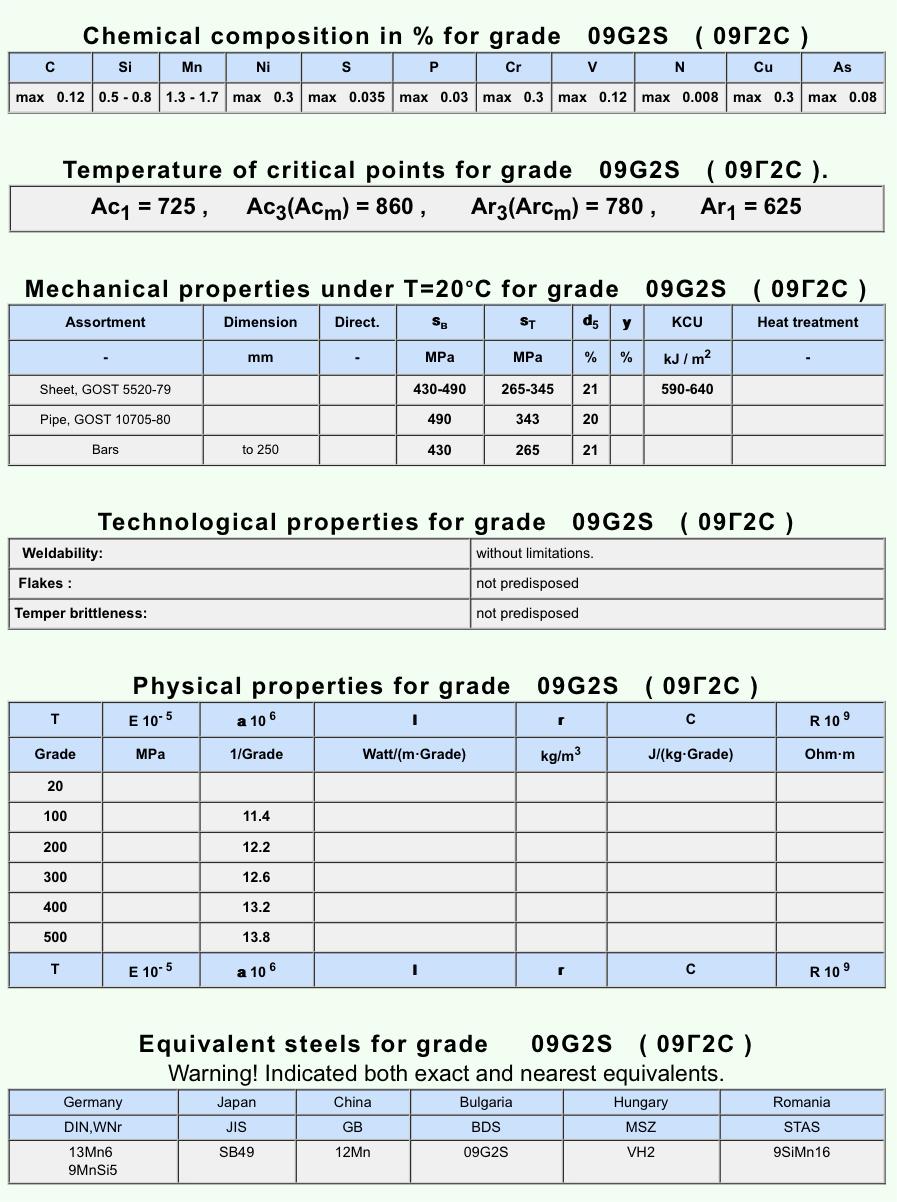

| MOSEBETSI OA K'hemik'hale OA 09G2S TŠEPE | ||||||||||

| C | Si | Mn | Ni | S | P | Cr | V | N | Cu | As |

| boholo 0.12 | 0.5-0.8 | 1.3-1.7 | boholo 0.3 | boholo ba 0.035 | boholo 0.03 | boholo 0.3 | boholo 0.12 | max0.08 | boholo 0.3 | boholo 0.08 |

Kenyelletso ea Sehlahisoa

Tekanyetso ea 09G2S ea Serussia ke maemo a tšepe tsamaisong e tloaelehileng ea tšepe ea Russia.Hape ke e 'ngoe ea lisebelisoa tse tsebahalang haholo Russia.09G2S tšepe ke tšepe ea sebopeho sa carbon, e nang le likarolo tse kenyeletsang carbon (C), silicon (Si), manganese (Mn), sebabole (S) le phosphorus (P).

09G2S tšepe e na le litšoaneleho tsa lik'habone tse mahareng le matla a phahameng, tse loketseng mefuta e fapaneng ea ts'ebeliso ea meralo, joalo ka kaho, marokho, liphaephe, tlhahiso ea likoloi joalo-joalo.E na le matla a phahameng a ho tsieleha, ho fana ka matla le ho ba le tšusumetso e matla, 'me e khona ho mamella meroalo e meholo le matla a ka ntle.

Ho ea ka litekanyetso tsa Serussia, tšepe ea 09G2S e hloka ho kopana le letoto la metsoako ea lik'hemik'hale, thepa ea mochine, metallography le litlhoko tsa tekheniki.Litlhoko tsena li kenyelletsa mefuta e mengata ea khabone, mefuta e mengata ea silicon, likahare tsa likarolo tsa alloying, matla a tlhahiso, bolelele, ts'ebetso e batang ea ho kobeha, joalo-joalo. Sepheo sa maemo a Russia 09G2S ke ho netefatsa hore tšepe e na le matla a loketseng le ho tšepahala. nakong ya tshebediso.

Hangata tšepe ea 09G2S e sebelisoa ha ho etsoa likarolo tsa meralo, joalo ka maballo, litšiea le marokho.E ka boela ea sebelisoa ha ho etsoa liphaephe tse nang le khatello e phahameng, lithapo tsa phetiso ea oli le khase le lisebelisoa tsa mochini.Matla a eona a lintho tse bonahalang, ho sebetsa le ho tšoarella ho etsa hore e be tšepe e sebelisoang haholo.

Weldability :

1.Kantle ho mefokolo- welding e etsoa ntle le ho futhumatsa le ho futhumala ha lifate ka mor'a moo

2.Limited weldability-welding-welding e ka khoneha ka tlas'a mocheso ho fihlela ho 100-120 grade le ho fokotseha ho fokolang ka mor'a mocheso oa lifate

3.Hard weldability-ho fumana tjheseletsa boleng hloka tshebetso e eketsehileng: futhumatsang ho fihlela ho 200-300 sehlopheng;the heating treeting ia annealing

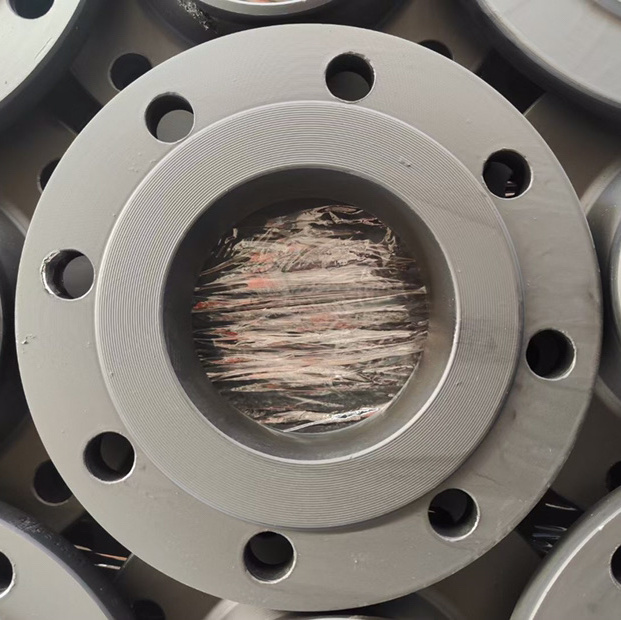

Khatello e phahamengtjheseletsa molala flangeke sekoahelo se sebedisoang ho hokela dipeipi le thepa.Hangata e na le li-flange tse peli tse bōpehileng joaloka disc, e 'ngoe le e' ngoe e na le bolelele ba molala o nang le lesoba.Li-flange tsena li kopanngoa ka ho cheselletsa molala oa li-flange tse peli hammoho.Khatello e phahameng butt welded flange e nang le molala e loketse khatello e phahameng le maemo a mocheso o phahameng, ka tiiso e babatsehang le matla.

Lintlha tse ka sehloohong:

1. Matla a phahameng: khatello e phahameng ea molala butt welding flange e amohela khokahano ea welding ea butt, e ka fana ka matla a phahameng le ho satalla, ho ikamahanya le khatello e phahameng le tikoloho e sebetsang ea mocheso o phahameng.

2. Ho tiisa hantle: Ka ho hokahanya ha butt welding, khatello e phahameng ea butt welding flange e nang le molala e ka fana ka tiiso e ntle le ho thibela ho lutla.

3. Ho kenya habonolo le tlhokomelo: The high pressure neck butt welding flange e bonolo ho e kenya, feela solder flanges tse peli hammoho, 'me u sebelise liboutu ho tiisa.Nakong ea tlhokomelo, bolt feela e ka tlosoa bakeng sa tlhokomelo.

4. Mefuta e mengata ea kopo: khatello e phahameng ea molala butt welding flange e loketse mefuta eohle ea tsamaiso ea liphaephe le lisebelisoa tsa lisebelisoa, tse kang lik'hemik'hale tsa lik'hemik'hale, oli, khase ea tlhaho, lifofane, likepe, matla a motlakase le libaka tse ling.

Ka bokhutšoanyane, khatello e phahamengtjheseletsa molala flangeke fastener e sebelisetsoang ho hokahanya tsamaiso e phahameng ea khatello le mocheso o phahameng oa mocheso, o nang le ho tiisa hantle, matla le litšobotsi tse bonolo tsa ho kenya le ho boloka.E na le lisebelisoa tse ngata tse fapaneng libakeng tsa indasteri.

1.Shrink mokotla–> 2.Small Box–> 3.Carton–> 4.Strong Plywood Case

E 'ngoe ea polokelo ea rona

Loading

Ho paka & ho Romela

1.Manufactory ea professional.

2.Litaelo tsa teko lia amoheleha.

Tšebeletso ea 3.Flexible le e loketseng ea lisebelisoa.

4.Theko ea tlhōlisano.

Teko ea 5.100%, ho netefatsa thepa ea mochini

6.Teko ea litsebi.

1.Re ka tiisa thepa e molemo ka ho fetisisa ho latela quotation e amanang le eona.

2.Teko e etsoa ho e 'ngoe le e' ngoe e loketseng pele ho pepa.

3.Liphutheloana tsohle li ikamahanya le thepa.

4. Sebopeho sa lik'hemik'hale se lumellana le maemo a machaba le maemo a tikoloho.

A) Nka fumana lintlha tse eketsehileng joang ka lihlahisoa tsa hau?

O ka romela lengolo-tsoibila atereseng ea rona ea lengolo-tsoibila.Re tla fana ka lethathamo le litšoantšo tsa lihlahisoa tsa rona bakeng sa referense ea hau.Re ka boela ra fana ka lisebelisoa tsa pipe, bolt le nut, gaskets joalo-joalo Re ikemiselitse ho ba mofani oa tharollo ea tsamaiso ea liphaephe.

B) Nka fumana lisampole joang?

Haeba u hloka, re tla u fa lisampole mahala, empa bareki ba bacha ba lebelletsoe ho lefa tefiso e hlakileng.

C) Na u fana ka likarolo tse ikhethileng?

E, u ka re fa litšoantšo 'me re tla li etsa ka tsela e nepahetseng.

D) U fane ka lihlahisoa tsa hau naheng efe?

Re file Thailand, China Taiwan, Vietnam, India, South Africa, Sudan, Peru , Brazil, Trinidad and Tobago, Kuwait, Qatar, Sri Lanka, Pakistan, Romania, France, Spain, Germany, Belgium, Ukraine joalo-joalo (Lipalo mona feela kenyelletsa bareki ba rona lilemong tsa morao-rao tse 5.).

E) Ha ke bone thepa kapa ho ama thepa, nka sebetsana joang le kotsi e amehang?

Tsamaiso ea rona ea tsamaiso ea boleng e lumellana le tlhokahalo ea ISO 9001: 2015 e netefalitsoeng ke DNV.Ka sebele re bohlokoa hore u re tšepe.Re ka amohela taelo ea teko ho matlafatsa ho tšepana.

Lihlopha tsa lihlahisoa

-

Mohala

-

E-mail

-

Whatsapp

-

Holimo