Flange ea khatello e phahameng e sebelisoa ho hokahanya liphaephe kapa lisebelisoa tse nang le khatello e phahameng ho feta 10MPa. Hajoale, haholo-holo e kenyelletsa flange ea khale ea khatello e phahameng le li-flange tsa ho itlama ka khatello e phahameng.

Traditional High Pressure Flange

Overview of Traditional High Pressure Flange

Flange e tloaelehileng ea khatello e phahameng ke karolo e sebelisang deformation ea polasetiki ea gasket e tiisang (oval gasket, octagonal gasket, lens gasket, joalo-joalo) ho finyella phello ea ho tiisa. E hokahane le pheletsong ea phala ho etsa hore phala le phala li kopane. Ho na le masoba holim'a flange, 'me li-flange tse peli li kopantsoe ka thata ke liboutu tsa stud.

Flange ea khale ea khatello e phahameng hangata e entsoe ka li-flanges tse peli, gasket le liboutu le linate tse 'maloa. Gasket ea ho tiisa e kenngoa pakeng tsa libaka tsa ho tiisa tsa li-flange tse peli. Ka mor'a ho tiisa linate, khatello e khethehileng holim'a ho tiisa gasket holim'a metsi e fihla boleng bo itseng, e leng se tla etsa hore ho be le deformation ea polasetiki le ho etsa hore ho be thata ho kopanya. Foromo ena e ka sebelisoa bakeng sa mecha ea litaba e ka tukang, e phatlohang, e chefo le linako tsa khatello e phahameng, empa ts'epahalo ea tiiso e fokola.

(Sets'oants'o sa khokahano ea khatello e phahameng ea flange-Welding Neck Flange)

Tse ling:Slip On Flange,Slip On Plate Flange

Likarolo tsa Flange ea Tloaelo e Phahameng ea Khatello

1. Molao-motheo oa ho tiisa ke oa deformation ea polasetiki

2. Khokahano ea bolted

3. Li-bolts li tla jara tsitsipano, khatello ea mocheso e fapaneng, nako ea ho khumama, torque le likhatello tse ling tsa ka ntle

4. E boima ebile e boima, 'me ho thata ho e kenya le ho e beha.

5. Ts'ebetso e sa tsitsang ea ho tiisa, haholo-holo maemong a thata (mocheso o phahameng, khatello e phahameng, le bohareng ba chefo e ngata), e atisa ho lutla, ho baka liphello tse tebileng.

Litšobotsi tsa ts'ebeliso ea Flange ea Tloaelo e Phahameng ea Khatello:

Flange ea khatello e phahameng e sebelisoa haholo-holo ha ho kenngoa liphaephe. Khokahano ea flange ea khatello e phahameng ke mokhoa oa bohlokoa oa khokahano bakeng sa kaho ea lipeipi. Haholo-holo e hokahanya kamano pakeng tsa liphaephe, e bapala karolo ea bohlokoa le bohlokoa. Khokahano e phahameng ea khatello ea flange ke ho lokisa liphaephe tse peli, lisebelisoa tsa liphaephe kapa lisebelisoa holim'a poleiti ea flange ka ho latellana, ho eketsa li-gaskets tsa flange pakeng tsa li-flange tse peli, le ho li tiisa hammoho ka liboutu ho phethela khokahanyo. Lisebelisoa tse ling tsa liphaephe le lisebelisoa li na le li-flange tsa tsona, tseo hape e leng tsa khokahanyo ea flange.

Ts'ebetso ea Flange ea Tloaelo ea Khatello e Phahameng:

1. Ho hanyetsa ho roala: litaba tsa Al2O3 ka har'a lera la ceramic la pipe ea tšepe e entsoeng ka ceramic e kholo ho feta 95%, 'me micro hardness ke HV1000-1500, kahoo e na le khanyetso e phahameng haholo ea ho apara. Khanyetso ea eona ea ho roala e phahame ka makhetlo a fetang leshome ho feta ea tšepe ea carbon e tingoeng, 'me e molemo ho feta ea tungsten carbide.

2. Li-ceramics tse sa khoneng ho senya ke lisebelisoa tse sa jeleng paate tse nang le lik'hemik'hale tse tsitsitseng tse tsitsitseng, ho hanyetsa kutu le ho hanyetsa acid, 'me li ka hanyetsa mefuta e sa tšoaneng ea li-inorganic acid, li-organic acid, li-solvents, joalo-joalo.

Khatello e phahameng ea Boithapollo ba Boithapollo

Kenyelletso ea Sehlahisoa ea Mofuta o Phahameng oa Boiketlo ba Boithaopo:

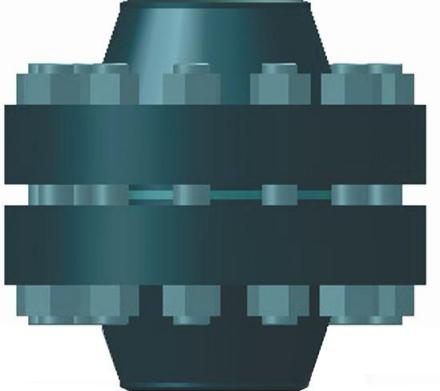

Khatello e phahameng ea "self tightening" flange ke mofuta o mocha oa khatello e matla ea flange, e leng bonolo haholoanyane ho hokahanya liphaephe tlas'a maemo a matla a ho sebetsa a kang khatello e phahameng, mocheso o phahameng le kutu e phahameng. Flange ea setso e itšetlehile ka deformation ea polasetiki ea gasket ho finyella mosebetsi oa ho tiisa, e leng oa tiiso e bonolo. Mokokotlo oa "high-pressure self tightening" flange ke tiiso e ncha e ikhethang, e leng tiiso e thata e entsoeng ke ho senyeha ha elastic ea molomo oa ho tiisa (T-arm) ea lesale la ho tiisa.

Sebopeho sa Profuct ea Mofuta o Phahameng oa Boiketlo:

Ka kakaretso e entsoe ka ferrule, sokete, selikalikoe sa ho tiisa le bolt.

1. Lesale la ho tiisoa ka tšepe: lesale la ho tiisa ke karolo ea mantlha ea li-flange tse nang le khatello e phahameng, 'me karolo ea eona ea sefapano e tšoana le sebopeho sa "T". Ka mor'a hore flange e bokelloe, rebar ea lesale la tiiso e tlamisoa ke lifahleho tsa ho qetela tsa lihlopha tse peli tsa lihlopha tsa HUB 'me li theha ka botlalo ka hlooho, e leng ho ntlafatsang haholo matla a karolo ea khokahanyo; Matsoho a mabeli a karolo ea "T", e leng molomo o koalang, le khoune e ka hare ea lenonyeletso la letsoho e etsa sebaka sa ho tiisa, se fetelang ka bolokolohi tlas'a matla a ka ntle (ka har'a moeli oa lihlahisoa) ho etsa tiiso.

2. Sokete: ka mor'a hore li-HUB tse peli tsa sokete li hatelloe ke ferrule, li hatelloa lekhopong la reng ea tiiso, 'me molomo o koalang o kheloha bokaholimo ba ka hare ba sokete, e khutlisetsang mojaro oa bokaholimo ba ho tiisa ka hare. ea sokete ho khutlela molomong oa selikalikoe sa tiiso, 'me e etsa setiiso se itšebetsang.

3. Ferrule: ferrule e ka fetoloa ka bolokolohi ka tataiso ea 360 ° bakeng sa ho kenya habonolo.

4. Lihlopha tse 'nè tsa liboutu tse chitja: ka kakaretso, ke lihlopha tse' nè feela tsa liboutu tse chitja tsa tangential tse phahameng tsa khatello e phahameng bakeng sa sete e 'ngoe le e 'ngoe ea likhatello tse phahameng tsa "self tightening flange" ho phethela ho tiea ka kakaretso.

Likarolo tsa Sehlahisoa tsa Mofuta o Phahameng oa Boiketlo ba Boipheliso:

1. Mokhoa oa ho tiisa: mokokotlo oa khatello e phahameng ea khatello e matla ke tšepe e ikhethang ho tšepe e ncha ea tiiso, ke hore, tiiso e thehoa ka ho senyeha ha elastic ea molomo oa ho tiisa (T-arm) ea reng ea tiiso, eo e leng ea eona. ho tiisa ka thata; Motsoako oa sleeve, ferrule le sealing ring li sebelisetsoa ho theha 'mele o tiileng o tiileng, o etsang hore matla a karolo ea ho hokahanya a be kholo ho feta matla a tšepe ea motheo ea pipe ka boeona. Ha e hatelloa, likhopo le molomo li bapala karolo ea matla le ho tiisa ka ho latellana, tse ke keng tsa tiisa tiiso feela, empa hape le ho matlafatsa phala, ho matlafatsa matla a kakaretso a karolo ea khokahano.

2. Thepa e tsitsitseng: Maemong a mangata, flange e matla ea ho itlama ka matla ka har'a khokahanyo e ka jara mojaro o boima ho feta phala ka boeona; Liteko tse senyang li bonts'itse hore flange e ne e ntse e tiile ntle le ho lutla ka mor'a hore pipeline e hlōlehe tlas'a boima bo boima.

3. Ho hanyetsa ho kobeha: palo e kholo ea liteko e bontša hore flange e ke ke ea lutla kapa ea lokoloha ha e jere mojaro o moholo oa ho kobeha. Teko ea 'nete: DN15 khatello e phahameng ea "self tightening" flange e cheselitsoe holim'a phala 'me e behoa tlas'a mekoloko e mengata e batang. Khokahano ea khatello e phahameng ea "self tightening" flange e ke ke ea lutla 'me liboutu li ke ke tsa lokoloha.

4. Compressibility: lits'ebetsong tse tloaelehileng tsa liphaephe, li-flange tse hatellang ka matla li ke ke tsa jara khatello e feteletseng; Ha boima bo phahameng ba khatello bo etsahala, boima bo bongata holim'a flange ea ho itlama ka khatello e phahameng e khethoa ke matla a ho qetela a phala.

5. Ho hanyetsa tšusumetso: boholo bo bonyenyane le bo kopanetsoeng ba geometri, bo ka mamellang matla a tšusumetso ao flange e tloaelehileng ea khatello e phahameng e ke keng ea e mamella; Mohaho o ikhethang oa tšepe ho sebopeho sa ho tiisa tšepe o ntlafatsa haholo ho hanyetsa ha oona.

Khanyetso ea kutu: khanyetso ea kutu ea lisebelisoa tse fapaneng e ka fihlela litlhoko tse khethehileng tsa ts'ireletso ea kutu ea libaka tse fapaneng tsa ts'ebeliso.

Nako ea poso: Dec-06-2022